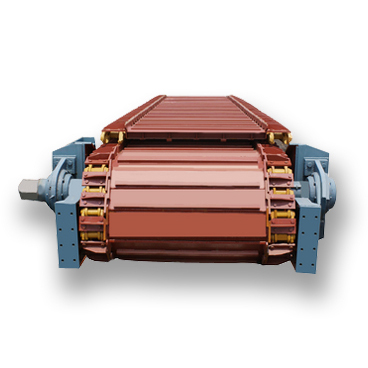

Heavy Duty Chain Feeder/Apron Feeder

HEAVY DUTY CHAIN FEEDER/APRON FEEDER

HEAVY DUTY CHAIN FEEDER/APRON FEEDER INTRODUCTION

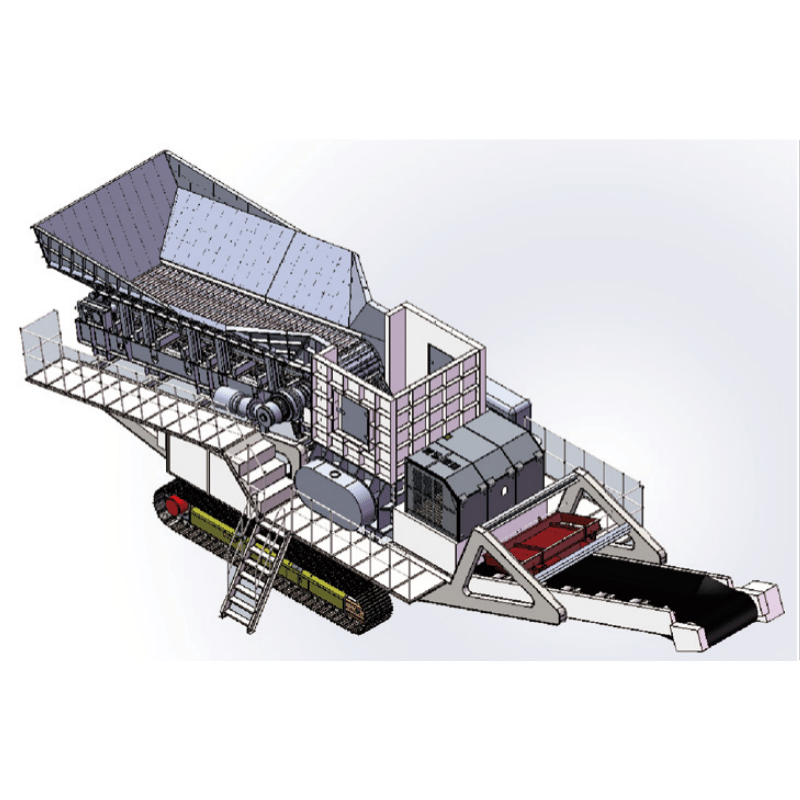

Heavy duty chain feeder is mainly used in the hopper and storage bin with a certain pressure, all kinds of large capacity materials short distance, continuous to all kinds of crushing evenly, screening or transportation equipment, is the most commonly used crushing station supporting a heavy feeding equipment.

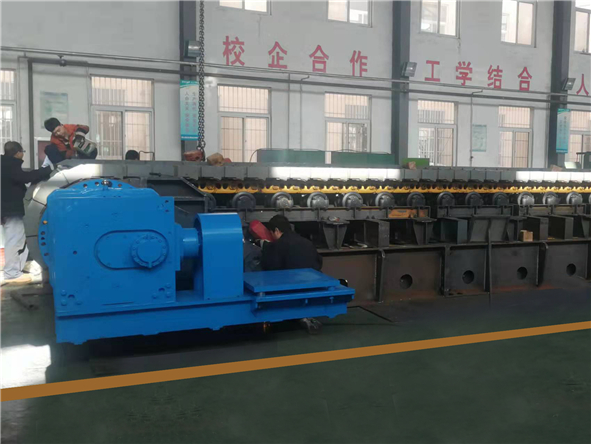

The GBZ series heavy-duty plate feeder produced by Tianhe Technology can complete the heavy feeding and conveying work under the harsh environment. It has great adaptability to the change of material size composition, temperature, viscosity and humidity, and the feeding is uniform, accurate and reliable. The machine has the advantages of reasonable structure, simple installation, disassembly and maintenance.

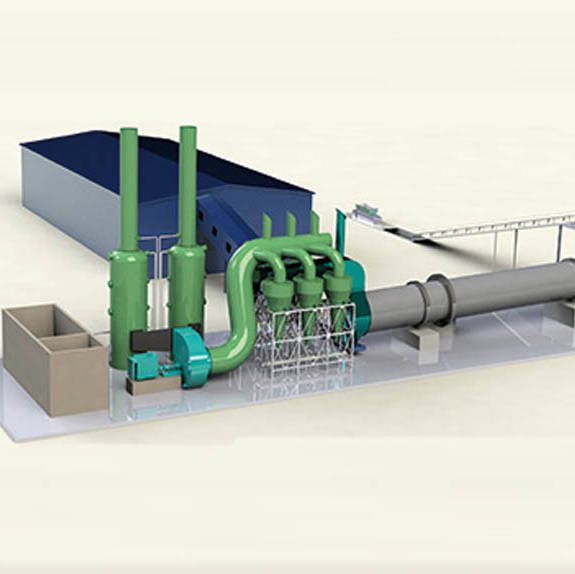

HEAVY DUTY CHAIN FEEDER/APRON FEEDER APPLICATION

Heavy-duty apron feeders are widely used in mining, metallurgy, building materials and coal industries. This machine is mainly used under the silo and hopper with a certain silo pressure, to send various large-capacity materials to various crushing, screening or transportation equipment in a short distance, evenly and continuously, especially when used feeding to primary crushing. It is not only suitable for processing coarse-grained materials, but also for fine-grained materials. It can also complete heavy work in harsh environments. It has great adaptability to changes in material particle size and composition, temperature, viscosity, and humidity, and the feeding is uniform and accurate, reliable in use, it is not allowed to unload the empty material, that is, the large material directly impacts the surface of the chain plate, and it is not allowed to blast on the surface of the chain plate. The machine can be designed with different installation angles according to the needs of the user, and the installation angle is between 0° and 25°.

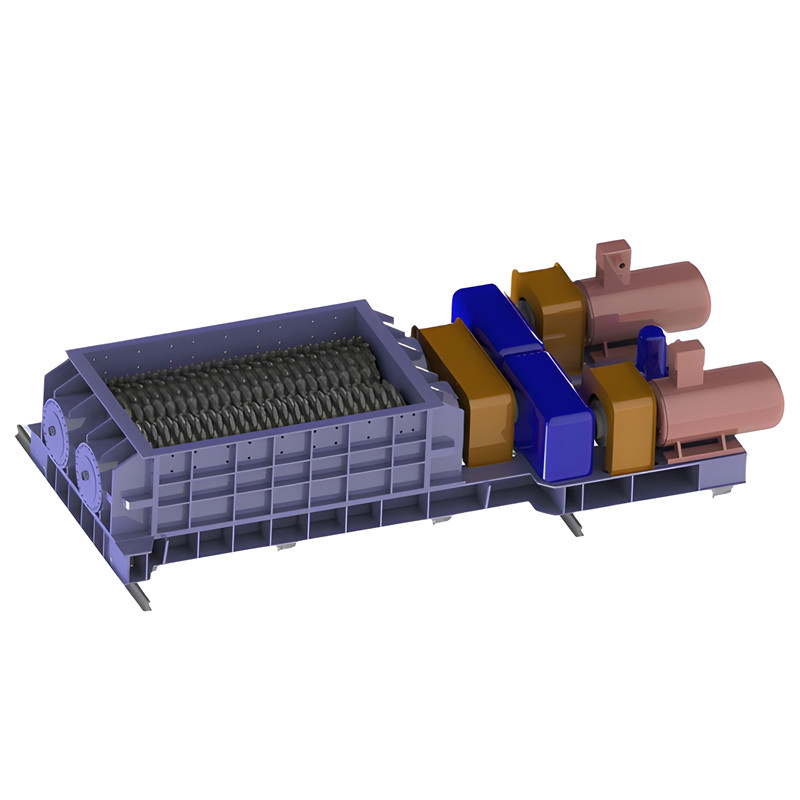

CRUSHER STATION TECHNICAL FEATURES

|

Model |

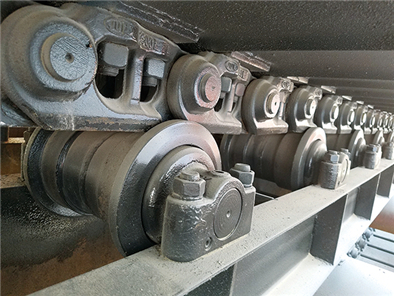

Chain plate width(mm) |

Chain wheel center distance(mm) |

Speed (m/s) |

Angel(°) |

Feeding material Size (mm) |

Capacity (t/h) |

|

GBZ1200 |

1200 |

4000 6000 8000 12000 14000 |

0.015-0.25 |

0-25 |

≤600 |

400 |

|

GBZ1500 |

1500 |

≤800 |

800 |

|||

|

GBZ1800 |

1800 |

≤1000 |

1200 |

|||

|

GBZ2000 |

2000 |

≤1200 |

2000 |

|||

|

GBZ2400 |

2400 |

≤1500 |

3000 |

Note:Conveying, installation Angle, feeding capacity, and material properties, stack density, installation space, etc., the above indicators are for user reference only.

PROJECTS PROFILE

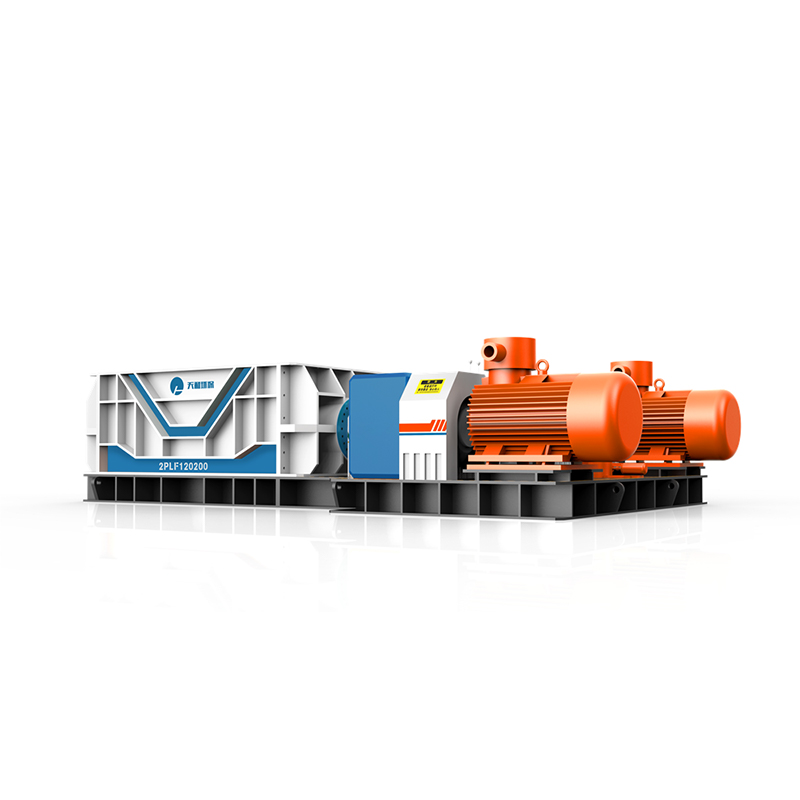

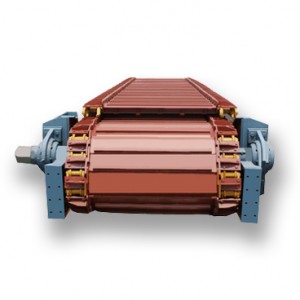

GBZ1500-6 HEAVY DUTY CHAIN FEEDER WITH CAPACITY 1000TON / HOUR

GBZ2400-12 HEAVY DUTY CHAIN FEEDER WITH CAPACITY 3150TON / HOUR

CHAIN PLATE WIDTH 2400 MM, CHAIN WHEELS CENTER DISTANCE 11350MM